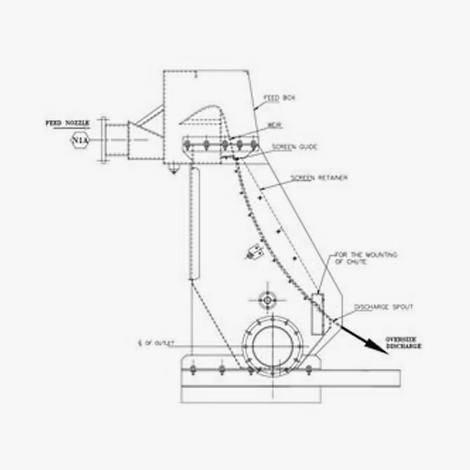

In the base type of INDOFAB Wedge Wire Screen (WWS) the feed enters through a Top rectangular feed box in a laminar manner passing over the knife edge screen ; The layer of solid & liquid particles strike the sharp edges of the wedge bar and are sliced off in a manner that smaller particles and liquids go downwards throught eh slots while the coarse partilcles slide down the screen towards discharge. Inorder to prevent blinding of such screens many optional provisions are suggested by INDOFAB such as Spray Jet washing Continous or intermitent, Pneumatic jerks to screens, Manual Slide down brush cleaning, motorized brush cleaning etc. Screening is essentially a low cost and very simple system to separate easily separable solids from flowing streams of liquid. These screens are though non-blinding and very long durable; The INDOFAB Screen with proper housing has all provisions to clean, Access, Clean or Even Replace the Screen at later stage or on damage. This makes INDOFAB WWS a right choice for life time of installation.

NDOFAB Wedge Wire Screen (WWS) s are effective Low Cost Solution for Screens of descrete solids or fibrous solids from a stream of flowing liquid. Most commonly used are 45 degree and 50 degree screens followed by 90degree and 120 degree designs.

As the slurry tends to be complex in nature we have to go higher degree screens with specialized feed arrangmenets such as parabolic feed, jet feed, adjustable flat jet feed. For Fine Screenings below 50 mesh usually two or more stages of screening helps to achieve effective results.

Used in many Industrial, Mineral and paper Application selection of the screen and its sizing forms the key to success of Installation of these Screens. At INDOFAB we expertise in Testing/recommending/selecting right type & size of screen based on the Process requirements.